I recently visited Bangladesh and was very impressed by several of the environmental initiatives this small, poor, and overcrowded nation of a growing 150 million has achieved.

Bangladesh has already managed to completely ban polythene plastic bags in 2002, is successfully using a much cleaner alternative vehicle fuel of compressed natural gas (CNG), is reducing greenhouse gas by keeping vast amounts of waste out of landfills, and uses cycle-rickshaws, probably the most-green urban transportation around, which are abundant all over the cities.

This nation, wedged between India on the west and north and Myanmar on the east, is one of the poorest and most crowded places in the world; it’s also going to be most affected by global warming. Most of the time when you hear about this country in the news it’s for some kind of natural disaster like Cyclone Sidr in November 2007 or about a lot of its land disappearing if all the glaciers of the Himalayas melt and raise the sea levels.

So maybe because of this or despite it, Bangladesh has the environment in mind.

One major problem is air pollution. The government has addressed this with the alternative fuel of compressed natural gas (CNG), which is less polluting than gas and diesel fuels. But industries such as brick factories are another major concern that several international agencies are addressing.

The Kyoto Protocol’s Clean Development Model (CDM) allows developed nations who signed the treaty to invest in clean technologies in developing nations. Bangladesh is a place that CDM is designed for and several CDM projects are operating successfully. One project is by an NGO named Waste Concern, which takes organic trash, turns it into salable compost, and sells the carbon credits in the overseas market. They keep the trash out of the waste stream and reduce greenhouse gases. In addition Waste Concern has created jobs for the poor and cleaned up the cities.

Making cleaner brick factories is the latest CDM project for a company that already has helped bring compressed natural gas to the country. Iftikhar “Sabu” Hussain, CEO of CNG Distribution Company, took me on a tour of the pilot clean-brick kiln on the outskirts of the capital city Dhaka.

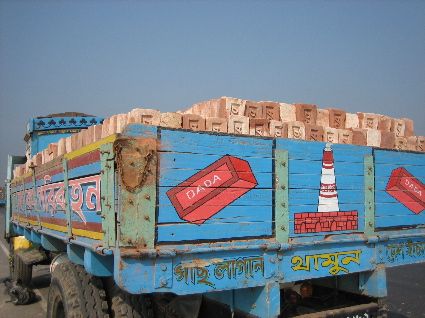

The countryside adjacent to Dhaka is emerald green farmlands starkly contrasted with dirty white brick-kiln smokestacks belching black smoke. Bricks are essential building materials here; everything is built with bricks and the industry is in demand.

These seasonal factories spring up in the dry season and are unregulated and abusive to workers, says Hussain. They burn coal inefficiently and the smoke and soot fills the air and falls onto the nearby crops.

Mr. Hussain’s brick kiln uses technology from China that infuses coal into the actual bricks themselves. When fired, the embedded coal hardens the brick and combusts, therefore using less external coal and releasing much less smoke.

This pilot clean-brick kiln releases less smoke than traditional ones.

This factory seemed to release less smoke when I visited, but it wasn’t perfect. Some smoke still escaped, but as Hussain says, it’s still in the experimental stage.

keeping the earth ever green

- Follow us on Twitter: @inthefray

- Comment on stories or like us on Facebook

- Subscribe to our free email newsletter

- Send us your writing, photography, or artwork

- Republish our Creative Commons-licensed content